Introduction

A force-sensing resistor is a material whose resistance changes when a force is applied. These resistors are made of a conductive polymer whose resistance changes in a predictable manner when a force is applied to its surface. These polymers are normally supplied as a sheet or ink that can be applied to a surface.

Types of Sensors

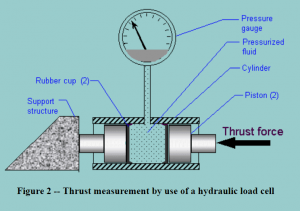

1) Load Cells

Basic Principle: This sensor records the pressure and changes in pressure on a pressurized fluid. For this sensor, the force measured is calculated with the equation F = PA, where P = measured hydraulic pressure (psi or N/mm2 ) and A = the cross-sectional area of the cylinder bore, A = p/4 D2 ( in2 or mm2 ). While this example is using an automotive brake cylinder, there are many uses of this sensor. In automobiles, the brake cylinder contains hydraulic fluid, which pushes apart two pistons that expand to put pressure on the brake drum. This, in turn, slows the vehicle. That is the conceptual explanation; in electronics, the pressure gauge would be replaced with a transducer that translates the force into a measurable electrical output. Strain gauge load cells are the most common type.

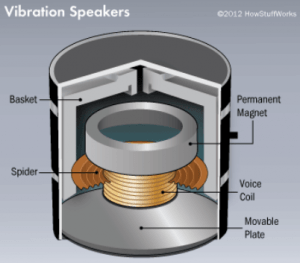

2) Transducer

Basic Principle: A transducer converts energy from one form to another, usually a signal in one form of energy to another. Transducers are often employed for automation, measurement and control systems where electrical signals are converted to and from other physical quantities such as force or light. Here is the example, a surface transducer.

This transducer is capable of converting electrical signals into physical vibrations, effectively turning any surface into a speaker if so desired. At the same time, the electrical signals produced by transducers can be responses to the physical environment, in this case, vibrations.

This is the interior of a vibration speaker. Electrons are pushed through the voice coil, producing a magnetic field that pushes or attract the permanent magnet. This movement creates the vibrations that produce sound waves.

These transducers require an understanding of polarity and the specific input power for them to function. They can be hooked up to an audio device for use. For the purposes of measuring or signaling pressure or touch, this transducer should be straightforward. This probably lands on the rookie scale or maybe reaches the competent level according to Sparkfun.

3) Force Sensing Resistor

Basic Principle: These sensors consist of conductive polymers that change resistance once a force is applied to their surface.

These resistors can be supplied as a polymer ink or a sheet. The sensing film is composed of both conductive and nonconductive particles. A force applied to the surface touches particles to the electrodes, changing the conductivity of the film. These sensors operate on a relatively simple interface.

This FSR will vary its resistance depending on how much pressure is being applied to the sensing area. The harder the force, the lower the resistance. When no pressure is being applied to the FSR its resistance will be larger than 1MΩ. This FSR can sense applied force anywhere in the range of 100g-10kg.

Skill level: Noob.

Limitation: These sensors are not very accurate for sensing the amount of force applied.

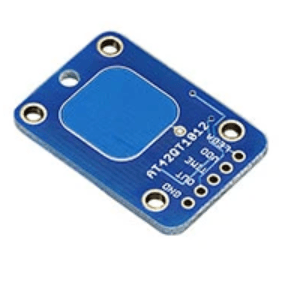

4) Touch Switch

Basic Principle: A touch switch is easiest explained as the switch that turns a lamp on and off just by touching a nondescript part of the surface of a lamp. These touch switches are placed on nonconductive surfaces where the electrode is triggered by body capacitance, the electricity moving through a person. The electrode continuously charges and discharges its metal exterior to measure the electrical current and to sense changes in the capacitance that can be detected when a person touches the surface it is positioned on. These are relatively simple in their installment and operation.

Skill Level: Rookie to competent level. Can have limited scope of measurement or use cases.

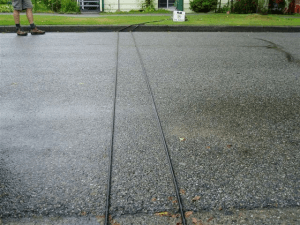

5) Pneumatic Tube Detector

Basic Principle: Pneumatic tubes are tubes of pressurized air that are often used to transport capsules or carriers, the objects that travel through the tubes such as carriers at a bank. As a sensor, these pressurized tubes are laid across roadways and send a high-pressure burst of air through the tube, which activates an air switch. This air switch, in turn, sends an electric signal to the receiver to record the instance. These are used for short term traffic counting and are relatively easy to use. These tubes are advantageous because they are cheap, easy to use, and self-contained. Unfortunately, they are not useful for high capacity roads and are not very durable.

Skill Level: This sensor should be easy to use, noob to rookie ranking.

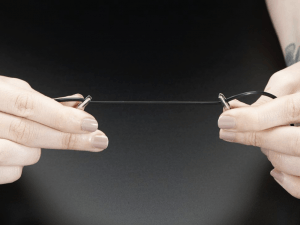

6) Conductive Rubber Cord Stretch Sensor

Basic Principal: This sensor measures stretch force. The resistance within the sensor will increase when an external force applied on (stretch or pull). The longer it is stretched, the larger the resistance.

Limitations:The rubber takes a few minutes to revert to its original length after the force is released. It’s not a linear sensor. Consider it a way to measure stretching motion instead of precise force.

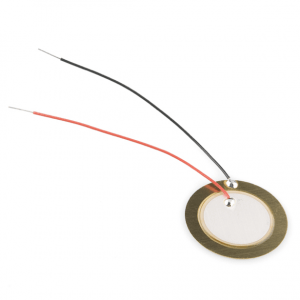

7) Piezo Vibration Sensor

Basic Principle: The piezoelectric sensor is used for flex, touch, vibration and shock measurement. It is most applicable in fast processes, such as explosion due to its quick responsiveness.

Basic principal:When structure moves, they experience acceleration. Piezoelectric shock sensor can generate a charge when physically accelerated (piezoelectric effect).

8) FlexiForce Pressure Sensor

Basic Principle: The harder you press, the lower the sensor’s resistance. Pressing hard, the resistance changes from infinite to ~300k. The sensor itself is thin and flexible, but the resistance does not change while being flexed. Resistance changes only when pressure is applied to the round area at the end of the sensor.

Another form of piezoresistive force sensor. They can detect and measure:

- Force from an applied load

- Rate of change of a force load over time

- Force thresholds to trigger appropriate action

- Contact and/or touch

Used as a presence sensor, weight sensor, pressure sensor (impact testing), etc.

9) Pressure-Sensitive Conductive Sheet

Basic Principle: Squeezing it will reduce the resistance, so it’s handy for making flexible sensors. Since its resistance changes with pressure, it can be used to create a basic analog sensor.

This conductive material (also known as “Velostat” or “Linqstat”)can be a addition for wearable/sensor hacking toolkit. For example, it can be made into step sensor by pasting under shoes.

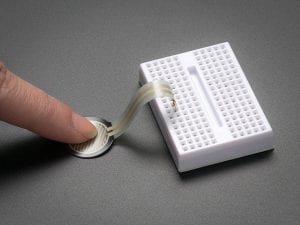

10) Round Force-Sensitive Resistor (FSR) – Interlink 402

Basic Principle: FSRs are sensors that allow you to detect physical pressure, squeezing and weight. These sensors are fairly low cost, and easy to use but they’re rarely accurate. They also vary some from sensor to sensor perhaps 10%. So basically when you use FSR’s you should only expect to get ranges of response. While FSRs can detect weight, they’re a bad choice for detecting exactly how many pounds of weight are on them.

FSR’s are basically a resistor that changes its resistive value (in ohms Ω) depending on how much its pressed. FSRs are made of plastic and the connection tab is crimped on delicate material. The best way to connect to these is to simply plug them into a breadboard or use a clamp-style connector like alligator clips, female header, or a terminal block.

11) FlexiForce Pressure Sen

Basic principle: This is a piezoresistive force sensor. The sensor itself is thin and flexible, but the resistance does not change while being flexed. Used as a presence sensor (someone standing), weight sensor, pressure sensor (impact testing), etc. This sensor ranges from 0 to 25lbs of pressure.

The harder you press, the lower the sensor’s resistance. Pressing hard, the resistance changes from infinite to ~50k. Resistance changes only when pressure is applied to the round area at the end of the sensor.

Skill Level: Noob.

Core Skill: Electrical Prototyping. If it requires power, you need to know how much, what all the pins do, and how to hook it up.

Additional Resources:

- Datasheet (ZFLEX A401-25)

- Product Page

- Bildr Tutorial

- Quickstart Guide

12) Tilt Sensor

Basic principle: This AT407 basic tilt switch can easily be used to detect orientation. Inside the can is a ball that make contact with the pins when the case is upright. Tilt the case over and the balls don’t touch, thus not making a connection.

There are numerous uses for these basic sensors, but keep in mind you might need to use some debouncing code, as the sensor isn’t immune to small vibrations and such.

Skill Level: Rookie

Core Skill: Electrical Prototyping. If it requires power, you need to know how much, what all the pins do, and how to hook it up.

Additional Resources:

13) Sensor Film Kit

Basic Principle: The Sensor Film Kit is a great new way to make custom-sized sensors out of force sensitive material. This kit includes one piece of black plastic sensor film (it’s thicker and more durable than Velostat but similar in function), two pieces of heavy aluminum foil, and two pieces of clear adhesive polyester film. The sensor film is super durable and changes its electrical resistance when force is applied. It’s a lot like Velostat but a bit more responsive. The aluminum foil is for electrodes and the clear adhesive polyester film is given to keep the sensors together. It’s a great way to make a FSR of any size for your microcontroller project.

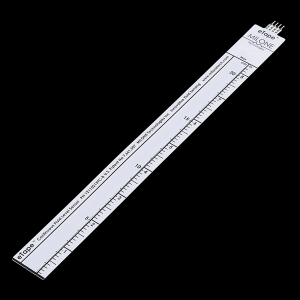

14) SoftPot Membrane Potentiometer

Basic principle: These are very thin variable potentiometers. By pressing down on various parts of the strip, the resistance linearly changes from 100Ohms to 10,000Ohms allowing the user to very accurately calculate the relative position on the strip. Can be used as an accurate positional indicator for CNC head positioning, variable user input (volume level input for example), straight user input (multiple button areas translate to given resistance levels), and many other applications.

Unit comes with adhesive backing. Connector is 0.1″ spaced and bread board friendly. However the connector does not fit nicely into standard female headers because the pins are too small.

Skill Level: Noob

Core Skill: Electrical Prototyping. If it requires power, you need to know how much, what all the pins do, and how to hook it up.

Additional Resources:

15) Liquid Level Sensor

Basic Principle: These sensors measure the level of a liquid. The sensors covering is sensitive to changes in pressure that would occur due to being immersed in a liquid. This allows the sensor to detect resistance changes that are inversely proportional depending on the distance from the top of the sensor to the top of the liquid. However, liquid level sensors can be sensitive to bending, so it is necessary to keep the sensor straight.

Skill Level: Competent

Core Skill: Electrical Prototyping

Additional Resources:

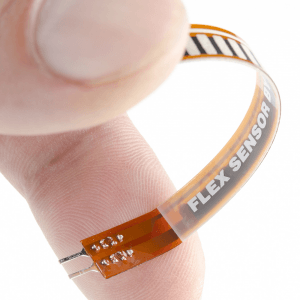

16) Flex Sensor

Basic Principle: One side of the sensor has polymer ink embedded with conductive particles. As the sensor is flexed or bent, the resistance in the current is increased due to the conductive particles being forced away from each other. This sensor is limited due to the fact that they can only measure flex in one direction.

Skill Level: Noob

Core Skill: Electrical Prototyping

Additional Resources: